1

/

of

11

QianLi Macaron Max Portable Double Pulse Integrated Battery Spot Welding Machine

QianLi Macaron Max Portable Double Pulse Integrated Battery Spot Welding Machine

Regular price

$39.45 USD

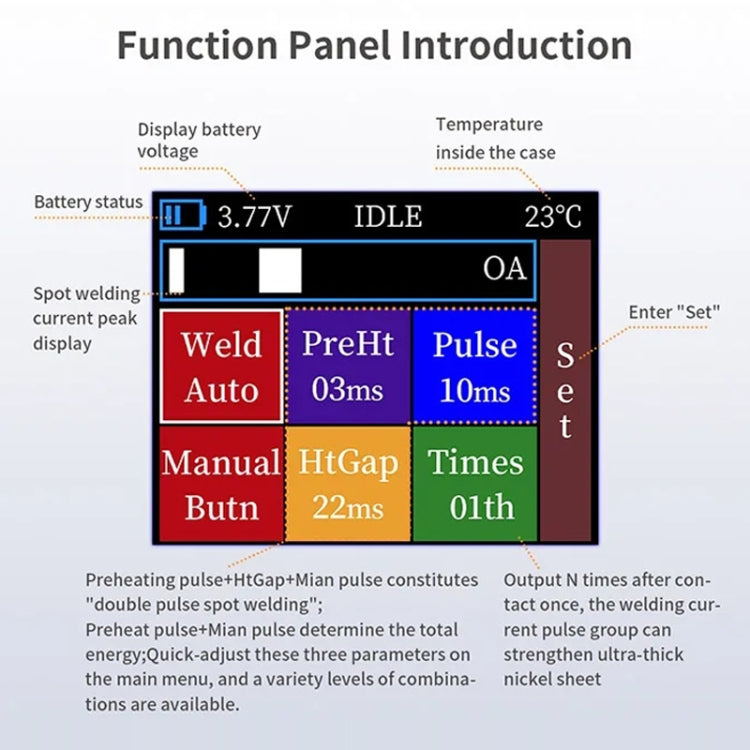

Regular price

Sale price

$39.45 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

1. Output Current: 650A(Max)

2. Input Interface: Type-C charging port

3. Input Parameters: 5V

4. Battery Capacity: 4000mAh/65C

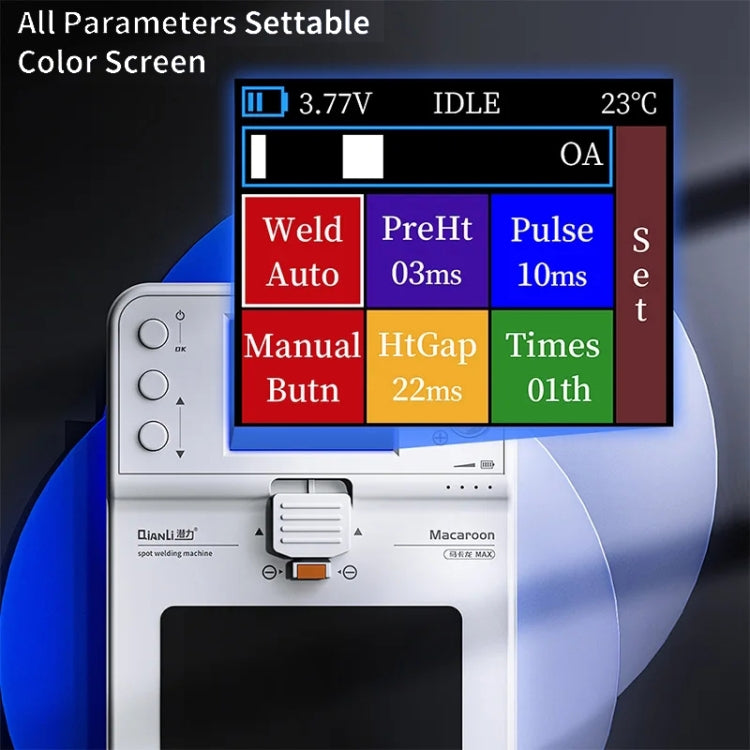

5. Macaron Max integrated spot welding machine, all parameters settable color screen/integrated spot welding/double pulse spot welding/auto burn-out

6. No need for separate external fixtures, a new attitude toward products, minimalist design, and more stable operation

7. Output a preheating pulse first, and then output the main pulse spot welding after a period, which is firm/stable/reliable

8. The color screen enables real-time visualization of spot welding parameters: Preheat, Pulse, HtGap, and Times (continuous welding spot); The mechanical button in the design supports adjusting spot welding parameters as needed

9. Place the cell on the silicone maintenance area of the spot welding machine, adjust the welding base clamp to clamp the welding part of the cell

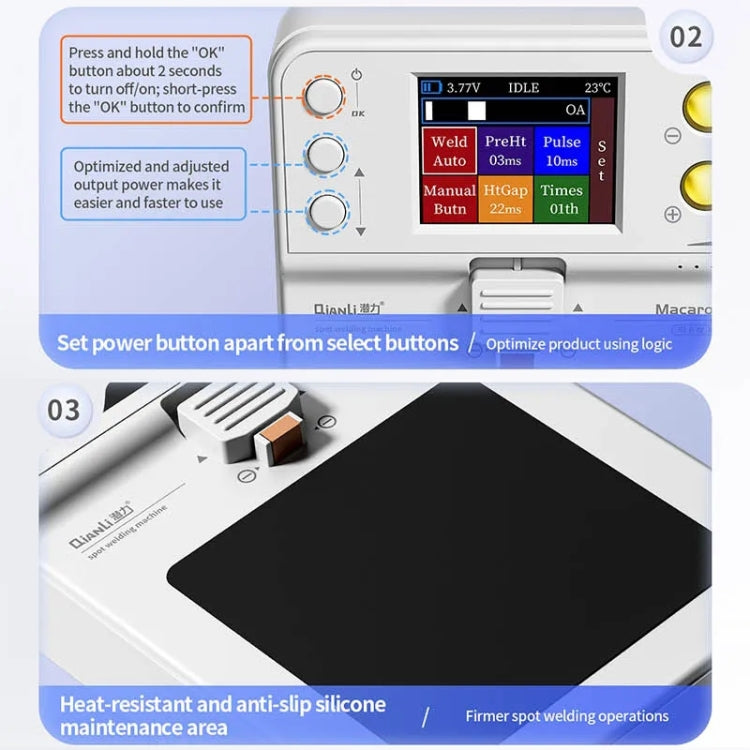

10. By selecting the "up" and "down" buttons, and confirming with the "OK" button, then the parameters of Preheat, Pulse, HtGap, and Times (continuous welding spot) can be adjusted to the appropriate spot welding power

11. Press the spot welding pen appropriately to ensure that the welding terminal is in good contact with the nickel sheet, without floating or poor contact, complete the welding after the current output

2. Input Interface: Type-C charging port

3. Input Parameters: 5V

4. Battery Capacity: 4000mAh/65C

5. Macaron Max integrated spot welding machine, all parameters settable color screen/integrated spot welding/double pulse spot welding/auto burn-out

6. No need for separate external fixtures, a new attitude toward products, minimalist design, and more stable operation

7. Output a preheating pulse first, and then output the main pulse spot welding after a period, which is firm/stable/reliable

8. The color screen enables real-time visualization of spot welding parameters: Preheat, Pulse, HtGap, and Times (continuous welding spot); The mechanical button in the design supports adjusting spot welding parameters as needed

9. Place the cell on the silicone maintenance area of the spot welding machine, adjust the welding base clamp to clamp the welding part of the cell

10. By selecting the "up" and "down" buttons, and confirming with the "OK" button, then the parameters of Preheat, Pulse, HtGap, and Times (continuous welding spot) can be adjusted to the appropriate spot welding power

11. Press the spot welding pen appropriately to ensure that the welding terminal is in good contact with the nickel sheet, without floating or poor contact, complete the welding after the current output

Specification:

| Package Weight |

|

Share